I am often asked about scale up and there is a common misconception that it only really matters when you get to the stage of full scale equipment selection. This mind-set often leads not only to project delays and cost overruns but can even lead to total failure at production scale.

I recall an example where I was asked to help on a tablet project as It was moving from small scale prototyping to trials on production rotary presses. The problem was that the tablets produced on the rotary press could not be made with the same hardness and rate of dissolution as the bench scale. At the same tablet hardness the rate of dissolution was longer for an identical formulation. What was the problem ?

This problem was a perfect illustration of why scale up is important even at the early stages of product prototyping. If the development engineers either neglect or do not understand the relationships between process parameters and product quality they will inevitably run in to trouble later on in the project.

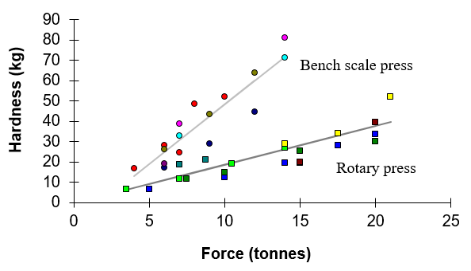

The below graph shows why this tablet development team ran into problems on scale up. The relationship between compression force (really stress) and tablet hardness is different from small scale to full scale, why ? The bench scale press selected for this project had a fundamental flaw, although the compression forces available were the same as production scale, the rate of compression was at least 10X slower. The fundamental mechanisms driving the bonding between particles in a tablet are such that at lower rates of compression stronger bonds are formed for the same maximum compression force. This in turn has the consequence that on scale up a higher force must be applied to achieve the same tablet hardness (normally a critical quality target) which results in slower dissolution characteristics(also a critical quality target).

The conclusion in this example was simple – it is impossible to scale up production of the bench scale press whilst maintaining both hardness and dissolution targets (unless production rates were reduced to uneconomic levels). This lack of basic scale up understanding resulted in major project delays since the only option was to modify the formulation to achieve the desired result.